Laser metal deposition

Exhibitor

Reis Robotics GmbH & Co. KG

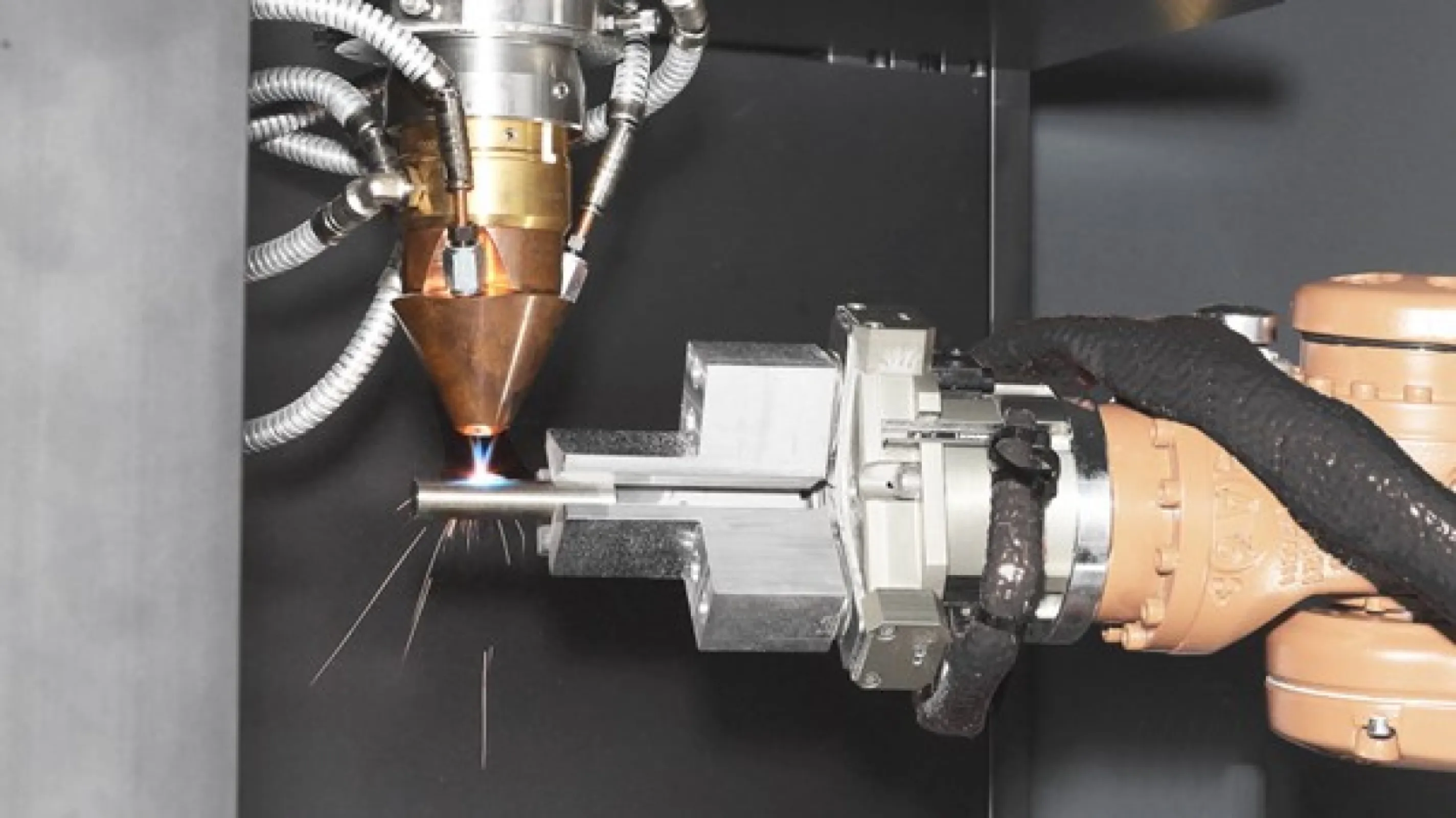

Laser metal deposition with the aid of powder-based or wire-shaped filler materials can be used for repair work, the application of wear and corrosion protection, and the production of 3D components (additive manufacturing).

How does laser metal deposition work?

A high-power laser is used as the heat source in laser metal deposition. During this process, a surface layer is created by means of melting and simultaneous application of virtually any given material. The filler material can be supplied either in powder form e.g. as metal powder, or with a welding wire. When laser metal deposition is carried out using powder, the laser usually heats the workpiece with a defocused laser beam and melts it locally. At the same time, an inert gas mixed with a fine metal powder is introduced. The metal powder melts at the heated area and is fused to the surface of the workpiece.

Wire-based laser metal deposition is a material-efficient 3D printing process used for producing metallic components